Talk about the heat treatment process of cast iron manhole cover

1.In order to improve the compressive strength of the well circle and increase the seating area of the bottom edge of the well circle, when assembling the well circle, the inner diameter of the well body should not exceed the nominal diameter of the well circle.

2. The structure of the well body platform should be a brick-concrete building structure, which must be firm and balanced. After the structural force is generated, the well circle and the grate seat can be assembled.

3. When assembling the grate seat, the bottom edge of the grate seat cannot hang in the air. You can refer to the installation steps of the well circle.

4. When placing the well ring and grate seat, it should be placed in time when the concrete at the bottom of the well ring and the grate seat (the thickness of the concrete should not be less than 30mm) has not condensed, and the well ring should be rammed hard or vibrated to make the well ring cement The soil is closely connected to enhance the contact surface between the well circle and the grate seat and the well platform.

5. After the product is assembled, the loading capacity should not exceed the specified carrying capacity of the product.

6. Before the top cover, the dirt in the well circle should be removed to prevent the contact force between the well cover and the well circle.

7. Start with tools.

8. If the manhole cover and rainwater grate are not installed in time, they must be placed in a safe place to avoid being run over by vehicles.

9. Strictly implement the above regulations for assembly, otherwise we will not bear any responsibility.

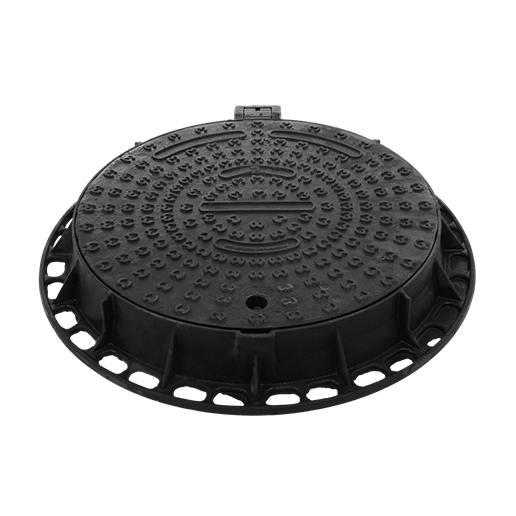

Ductile cast iron is made of gray cast iron and inoculated to obtain spherical graphite, which improves the physical properties of cast iron, especially the plasticity and ductility, so as to obtain stronger compressive strength than carbon steel. Super-heavy cast iron is generally made of gray iron. The compressive strength, plasticity and ductility of gray cast iron are far lower than steel, but the tensile strength is very similar to that of steel. They are common cast irons with poor physical properties. Cast iron design load Level: -Level 20 -Level 10. Generally known as Φ700 light ductile iron manhole cover, the outer specification is 700. The aperture of the manhole cover is 740.

Cast iron manhole cover anti-theft system

Cast iron manhole covers have the advantages of good patience, strong corrosion resistance, good plasticity, high strength, high forging work efficiency, and low production cost. It is warmly welcomed by urban roads, expressways, communications, power engineering, drinking water, residential quarters, colleges and other parks. The disadvantage is that it is often stolen, which creates risks. Therefore, manufacturers aim at this disadvantage and make the following anti-theft system methods for cast iron manhole covers:

The anti-theft system of mechanical equipment can be added with a metal watch chain, which can connect the well ring and the cast iron manhole cover as a whole. Safety protection effect, the manhole cover cannot be opened without special things. This kind of spring leaf is one of the methods of the anti-theft system.

There are also some special cast iron anti-theft system manhole covers with a new type of anti-theft system with overall planning. The lock and key are made of high toughness and anti-embroidery copper. The anti-theft device is corroded during daily use, making it impossible to open the manhole cover. The new five-proof two-layer cast iron manhole cover adopts the overall planning of the manhole cover and the well ring, and the hardware lock of the turntable mechanical equipment has the effect of an anti-theft system.